Wholesale Professional square shape chain in China

Professional square shape chains have emerged as a prominent component in various industries, owing to their unique design and versatile applications. In this article, we will delve into the components, connection methods, stability, and strength of Professional square shape chains. Through a comprehensive examination of these aspects, we aim to unlock the potential of Professional square shape chains and shed light on their significance in industrial processes.

1. Components of Professional square shape chains

Professional square shape chains are primarily composed of several critical components that work together to ensure functionality and durability. These components include:

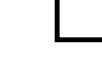

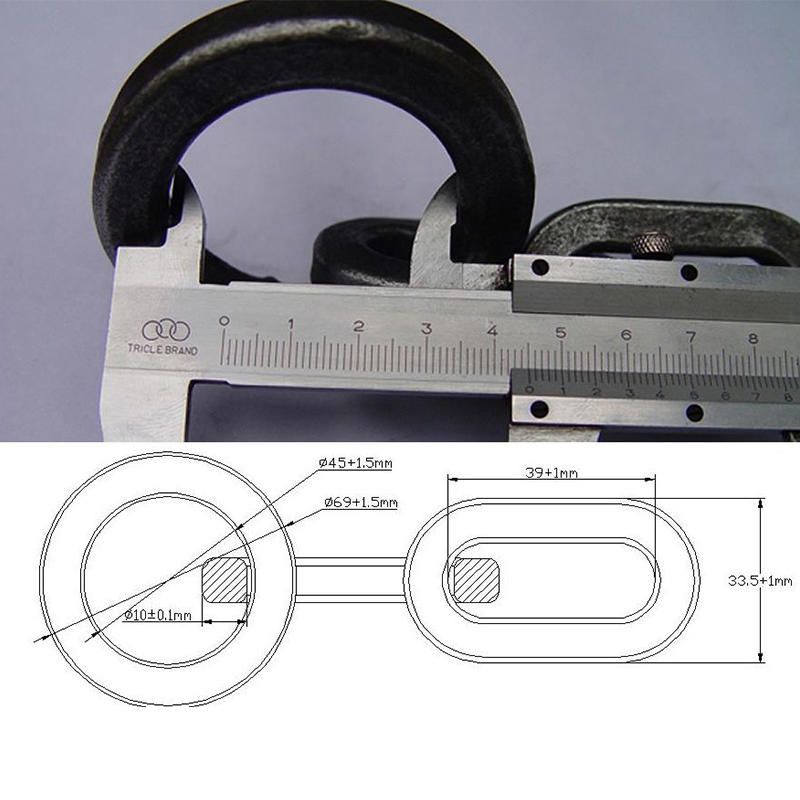

1.1. Links: The links of a Professional square shape chain form its basic building blocks. These links are usually square in shape, hence the name, and are connected in a continuous loop. The material used for links may vary depending on the specific application, with options ranging from metal (such as steel or stainless steel) to plastic.

1.2. Pins: The pins serve as pivotal components that connect the links of a Professional square shape chain. They are responsible for maintaining the integrity and flexibility of the chain. Pins can be permanently fixed or removable, depending on the design requirements.

1.3. Rollers/Bushings: In certain applications, Professional square shape chains may incorporate rollers or bushings within the links. These components reduce friction and enable smooth operation by facilitating the movement of the chain along the desired path.

2. Connection Methods of Professional square shape chains

Professional square shape chains are connected through different methods to accommodate specific applications and requirements. Here are some common connection methods:

2.1. Welding: Welding is a permanent connection method widely used in industrial settings. It involves melting the links at their contact points and fusing them together. Welded connections provide excellent strength and stability, making them suitable for heavy-duty and high-load applications.

2.2. Bolted Connections: In applications where disassembly and reassembly are necessary, bolted connections are preferred. This method involves securing the links together using bolts, nuts, and washers. Bolted connections provide the advantage of easy maintenance and replacement.

2.3. Riveting: Riveting is a connection method that utilizes metal rivets to join the links of a Professional square-shaped chain. This method ensures a secure connection while allowing flexibility and strength. Riveted connections are commonly used in applications where vibration resistance is crucial.

2.4. Snap-Fit Connections: Snap-fit connections involve interlocking the links of a Professional square shape chain, creating a secure connection without the need for additional fasteners. This method offers quick assembly and disassembly, making it suitable for applications that require frequent maintenance or adjustment.

2.5. Magnetic Connections: In specialized applications, Professional square shape chains can be connected magnetically. This connection method utilizes magnetic forces to secure the links together, providing ease of assembly and disassembly.

3. Stability of Professional square shape chains

The stability of Professional square shape chains plays a pivotal role in determining their overall performance and functionality. Several factors contribute to the stability of these chains, including:

3.1. Chain Tension: Proper tensioning of a Professional square shape chain is essential to maintain stability during its operation. Insufficient tension can lead to slackness and chain slippage, while excessive tension can cause premature wear and damage to the components.

3.2. Load Distribution: Professional square shape chains distribute loads evenly across their links, ensuring that the weight or force is adequately supported. Uneven load distribution can lead to stress concentration and may compromise the stability of the chain.

3.3. Alignment: Accurate alignment of a Professional square shape chain is crucial for optimal stability. Misalignment can result in increased friction, wear, and decreased efficiency. Regular maintenance and alignment checks are necessary to ensure stable operation.

3.4. Lubrication: Proper lubrication of Professional square shape chains reduces friction between the components, ensuring smooth movement and preventing premature wear. Lubricants also help to dissipate heat generated during operation and enhance the chain's stability.

4. Strength of Professional square shape chains

Professional square shape chains are designed to exhibit significant strength and robustness in various applications. Key factors influencing the strength of these chains include:

4.1. Material Selection: The choice of materials significantly impacts the strength of Professional square shape chains. Factors such as the required load capacity, environmental conditions, and desired durability influence the selection of materials, which can range from high-strength steel to specialized alloys or reinforced plastics.

4.2. Chain Pitch: The pitch, or the distance between the centers of adjacent links, affects the strength of a Professional square shape chain. Smaller pitches generally result in stronger chains capable of withstanding higher loads.

4.3. Chain Design: The design of Professional square shape chains is engineered to optimize strength and minimize stress concentration. Various factors, including link shape, geometry, and reinforcement techniques, are considered during the design process to enhance the chain's strength and durability.

4.4. Ultimate Tensile Strength: The ultimate tensile strength determines the maximum load a Professional square shape chain can withstand without breaking. This parameter is crucial in applications that subject the chain to high loads or dynamic forces.

Conclusion

The components, connection methods, stability, and strength of Professional square shape chains play vital roles in their efficient operation and applicability across various industries. By understanding these aspects, engineers and designers can optimize the performance and durability of Professional square shape chains, ensuring their successful integration into complex industrial systems. The versatility and strength offered by Professional square shape chains make them a sought-after component, capable of withstanding demanding conditions and enabling the smooth operation of critical industrial processes.

English

English 中文简体

中文简体