Anti-slip chains

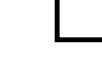

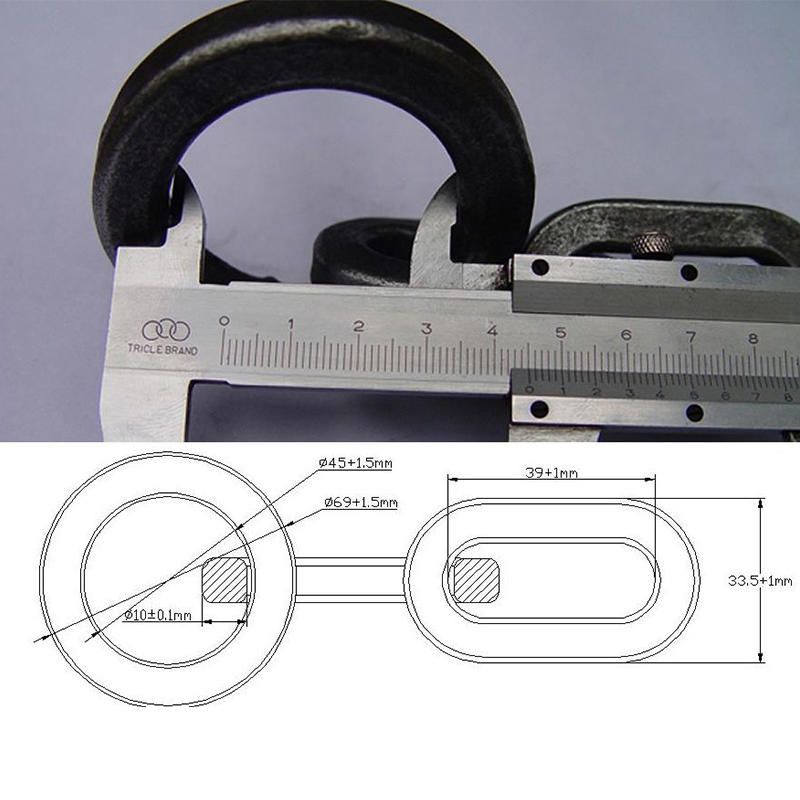

Brief introduction: Anti-skid chain is generally made of steel chain or rubber chain (tpu), the principle is simple, easy to install the anti-skid chain for trucks, and practicality is very strong. According to the structure, there are two kinds of anti-skid chains: one is the one that has been connected into a hood; the other one is several individual anti-skid chains that are cross-mounted, which is simpler and cheaper, but not as convenient to install as the former. Note on the use of anti-slip chains: The following aspects should be noted in the use of anti-slip chains: It is better to install the anti-slip chains before traveling, rather than after encountering icy anti-slip chains on snowy roads, because temporary parking to install anti-slip chains is more troublesome than installing them in advance, which is also not conducive to safety. Install and remove the vehicle before parking in a safe area. If you are on a busy road, you need to set up the necessary traffic warning signs. Do not install anti-skid chains on flat tires. Anti-skid chains also have size restrictions, which are suitable for different wheel sizes and tire widths respectively, so pay attention to choosing a chain that matches the wheel size. After installing the chains, the driving speed should not exceed 40Km/hour, and avoid sudden acceleration or deceleration as much as possible. Please remove the chains in time when the vehicle enters the road without using the chains. Anti-skid chains are not designed for trailers or tractors. In cold areas, some vehicle owners make their own chains, which can solve the problem temporarily, but it is not worth promoting. How to install anti-skid chains]: Due to the freezing weather and snow on the road, many cars are fitted with anti-skid chains to avoid accidents. The principle of anti-skid chains is to concentrate the gravity of the vehicle on several points of the chain, producing a huge pressure, rolling through the ice and snow layer straight to the road, thus increasing the friction and increasing the safety factor of the vehicle driving. The editor found some small knowledge about anti-skid chains, hoping that the public travel safely. Installing anti-skid chains is a skill course that people will probably never use in their lives. But as those of you who live in cold climates, it is very useful. It may sound daunting to people, but actually installing and removing chains is a very quick process, even when done in bitterly cold weather. With 15-30 minutes of expert guidance, you'll be driving safely and reliably through the winter in no time. It is if you can install and remove the chain in your driveway or some relatively safe place. Of course, when you have to install or remove them on the road, make sure you do it on a safe and level roadside. Wherever possible, be sure to leave yourself at least 10 feet of open space in front of and behind your vehicle, allowing you plenty of room to move the chain. Also make sure you have activated your parking brake before your hand touches anywhere near the tire to avoid an accident. It is a good idea to support the tires with wooden blocks as an additional protection. Last, but not least, clean the excess snow off your tires. First, make sure your car is driven by the front or rear wheels, as the chain must be hooked to the set of tires that play a major role. Once you know which set of tires you need to apply the chains to, clean as much snow off the tires as possible to create a flat surface. Spread the chain under the car and place the first gear of each chain attached to the ground against the tire. Make sure the grainy side of the chain is facing the ground, this is the part of the chain that gives the traction. If you have a rear-wheel drive car, you will have to bite the chain backwards. If it's a front wheel, you'll want to push it forward. Check to make sure that each tire is holding the chain and that each side is lapped with a strand of gear. Then get in the car, start the engine, and slowly and carefully take the chains and push the car forward or backward about 2 feet. Once your tires are positioned at right angles to the chain, pull off the ports that lap over the top of the tires. Each end must be a perfect fit for the entire chain gear. Give yourself 1 to 2 inches of clearance first, then bolt the unit tight through the two opposite sides of the chain link. Each rubber ring of the chain has 4 metal hooks evenly spaced around it. Each metal hook is secured in a criss-cross pattern on the hubcap side of the tire. This ensures that your chain will not slip off. The chains should now be securely fitted and ready to give you traction on snowy roads. However, don't assume your chains will keep you flying through the rough driving conditions. Start slowly and pay attention to the sounds your car makes, that may be a warning that your chains are loose or that your tires are not mounted properly (question the chain issue). No matter how safe they are to use, it's not wise to drive a tire with chains on it at 40 mph. Bad weather doesn't last forever, so when it stops snowing, it's time to remove the chains from your car. Do not, under any circumstances, drive with chains on non-snowy roads, as this can seriously damage your tires. Removing chains is much easier than installing them. Just do the opposite steps, remove the chains and store them in a dry place for the next winter. [Types of Anti-skid Chains]:1) Iron chain --- Some are steel chains, this kind of chain is widely used, and is also the common and classic one. Advantages and disadvantages at a glance, the advantage is that the price is very cheap, strong and durable. The disadvantage is that the noise, disassembly and installation difficulties, heavy, the worst is the wear and tear on the tires more serious. Because the chain is fixed by steel wire in addition to the front and back of the tire, the chain exposed on the surface of the tire is free to move back and forth, in the anti-skid process, the chain - the ground - the tire between the mutual movement of the tire to make the tire doubly hurt some people describe like a file to utter the tire. This kind of chain shape has a simple trapezoid and diamond, the former is mostly used for trucks and the latter is used for small cars. The ordinary diamond-shaped chains for small cars are about 140-180 yuan (one pair/2 tires), and the cheap ones are about 80 yuan. This kind of iron anti-skid chain is now gradually withdrawing from the car supplies market, and is replaced by the following 2 kinds of anti-skid chains. 2)Bull bar chain---This is a chemical mixture of PVC, PP and PT, which is a relatively modern anti-skid device for vehicles developed recently. It is easy to install as long as the chain is laid flat on the ground and the car is slowly driven up and then fixed on the driving wheels. The price is 260-390-500 yuan (one pair/2 tires). It fluctuates with the change of weather and the price of raw materials. 3)Rubber chain---The shape of this rubber chain is basically similar to that of a bull bar chain, except that the rubber used is of good quality and can have strong tensile strength, and then there is the nylon wire arranged in the rubber to resist tensile strength. Just like the manufacture of car tires, the nylon wire plays the role of tensile strength and reinforcement, and there are steel nails on the rubber to play the role of anti-slip. Although the appearance is similar to the bull bar chain, it is obvious that the overall thickness and mesh are larger than the bull bar chain. Tires are a kind of product, it is a kind of high-tech composite product, which contains about 20 kinds of parts made of more than 200 different materials and products; tires are also a kind of culture, which contains human ingenuity and wisdom; tires are a kind of safety, which is related to The safety of each person's life in the automobile era, is a consumer product that you and I must be careful to treat. But in the end, tires are for the car service. Tires are one of the important components of the car, its role is mainly: to support the full weight of the vehicle, bearing the load of the car; transmission of traction and braking torque, to ensure the adhesion of the wheels and road; reduce and absorb the vibration and impact of the car when driving, to prevent severe vibration and early damage to auto parts, adapt to the high-speed performance of the vehicle and reduce the noise when driving, to ensure the driving Safety, handling stability, comfort and energy-saving economy. Tires are generally divided into tubular and tubeless tires. An inner tube tire, as the name implies, has an inner tube filled with compressed air inside the outer tire. Its main disadvantage is the high driving temperature, not adapt to high-speed driving, can not fully ensure the safety of driving, when using the inner tube in the tire in the state of tension, slightly punctured will form a small hole, and the tire quickly depressurized. Tubeless tires do not use the inner tube, air directly into the inner cavity of the outer tire. This eliminates the friction between the inner and outer tire, and makes the heat dissipate directly from the rim, reducing the temperature by more than 20% compared to ordinary tires. Tubeless tires improve driving safety, can continue to drive when the perforation is small, and are easier to repair midway than tubed tires, without dismantling the rim, and can improve the cushioning performance of the tire and increase the service life of the tire because of better flexibility. Tires can be divided into: bias tires and radial tires by structural design. Bias tires are named because the cord is crossed in a diagonal arrangement. Characterized by high tread and sidewall strength, but the sidewall stiffness, poor comfort, due to the high speed between the curtain ply movement and friction, and is not suitable for high-speed driving. With the continuous improvement of radial tires, bias tires will be largely eliminated. Radial tires of the cord fabric layer is equivalent to the basic skeleton of the tire, its alignment direction and tire radial section consistent. As driving tires to withstand the larger tangential force, to ensure the stability of the cord, in its external and a number of layers made of high-strength, not easy to stretch the material with the bundle layer (also known as the hoop layer), the direction of the cord and the radial section is a large angle of intersection. Radial tires compared with ordinary slanted tires, elasticity, good wear resistance, rolling resistance, good adhesion performance, good cushioning performance, large load-bearing capacity, not easy to puncture; disadvantage is that the side of the tire is easy to crack, due to the lateral deformation, resulting in slightly poorer lateral stability of the car, manufacturing technology requirements, high cost. Here mainly introduces the common radial tire structure 1. tire tread: 1 thick rubber ply, provides a contact interface with the ground, but also has the performance of drainage and resistance to old. 2. Crown Band Ply: A double or 3-ply reinforced band ply provides flexibility in the vertical direction and extremely high lateral rigidity, providing steering force. 3. sidewall: the sidewall houses and protects the carcass cord ply, which functions to hold the tire tread to the rim. 4. lip part for fixing to the rim: the wire loop of the lip inside it holds the tire firmly to the rim, binding it together. 5. airtight ply: it ensures that the tire has good airtightness and maintains the correct tire pressure. Specifications and its logo some owners of their car tires on the meaning of the logo is not very clear, the following on the tire side of the logo to explain. For example, a tire marked as "P 225/65 R 16 89 H", where: "P" refers to car tires (to distinguish the tires applicable to trucks or other models). "225" refers to the width of the tire section, which is the width between the two sidewalls (in millimeters). This width varies depending on the width of the rim the tire is matched to: wide rims with wide tires, narrow rims with narrow tires. The width generally indicated on the sidewall is the width when the tire is mounted to the rim of the recommended width. "65" is the flat ratio of the tire, which is the ratio of tire width to tire height, here the tire height is 65% of the tire width, the smaller the value, the more flat. "R" refers to the structure of the tire, indicating that the tire is radial structure, which means that its cord ply is arranged in a radial pattern in the carcass. "B" indicates that the tire is oblique structure, the current oblique structure of the car tire no longer exists. "16" indicates the rim diameter (in inches), this tire must match the 16-inch rim, otherwise it can not be installed. "89" indicates the load index: this tire has a maximum load of 580 kg. different load indexes represent different maximum loads. "H" indicates the speed class: the maximum speed of this tire is 210 km/h. Different letters indicate different speed classes. The following table shows the maximum speed of each speed class, which is applicable to all brands of tires: Speed code Maximum speed (km/h) M 130N 140P 150Q 160R 170S 180T 190U 200H 210V 240W 270Y 300 truck anti-skid chains, anti-skid chains, anti-skid chains manufacturers

English

English 中文简体

中文简体